The laser metal pipe cutting machine has become more and more intelligent, which has benefited every customer in the protective fence industry.

With the development of real estate in recent years, it has driven the development of the industrial chain. The demand of the protective fence industry is huge, and there are higher processing efficiency requirements and quality of the protective fence products. It is said that one of every two protective fence cutting manufacturers is using a metal pipe laser cutting machine.

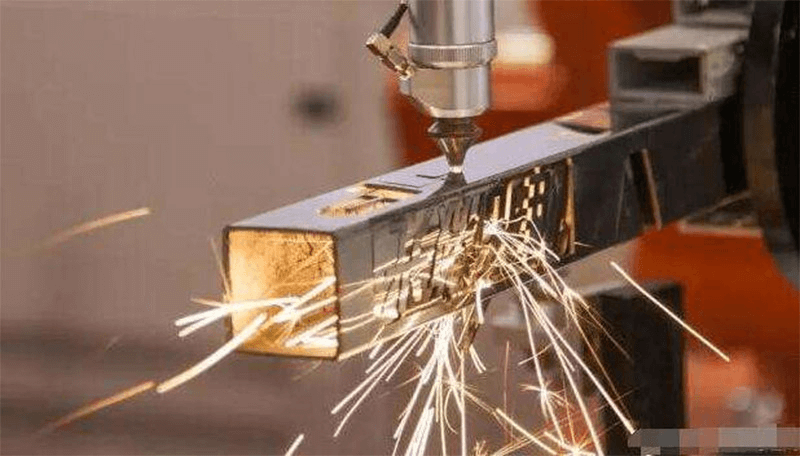

The tube laser cutting machine can realize a series of functions such as fully automatic bundle feeding, CCD tube cross-section recognition system, tube floating custody mechanism, automatic sorting and blanking of finished pipe fittings, intelligent remote monitoring, and automatic tube sheet length measurement.

Cutting fences include square tubes, rectangular tubes, round tubes, elliptical tubes and special-shaped tubes, support tube profiles such as angle steel, channel steel, I-beam, T-shaped steel, etc. The materials that can be processed include carbon steel pipes, stainless steel pipes, and aluminum alloy pipes. , Copper alloy tube, titanium alloy tube and other metal tube materials.

The pipes used in the protective fence industry are diverse and have different diameters, which can be fully automatically cut to achieve diversified processing.

With the development of lasers and the Internet, metal pipe laser cutting machines have become more and more intelligent, which has benefited every customer in the protective fence industry and replaced the traditional way.

.png)