Automobile Manufacturing

As a high-tech and highly concentrated industry, automobile manufacturing faces very severe market challenges. Laser is an advanced productivity and has been widely used in the production and processing of more than 60% of auto parts. Reduce labor costs and provide standardized production processes

Laser cutting technology is considered to be very beneficial for processing plastics and textiles in vehicles, and you can benefit from the clear cut of the laser cutting machine when producing many components for the interior and exterior of the car. Textiles can be marked and cut with lasers, resulting in a variety of design options in textile processing

Parts are very important in the automotive industry, usually using data matrix codes and alphanumeric characters. Laser marking machines can permanently store these important information on almost any material: whether the part is metal or plastic, laser marking can ensure durability, clarity and rapid processing

-

Metal

-

Non-metal

-

Marking

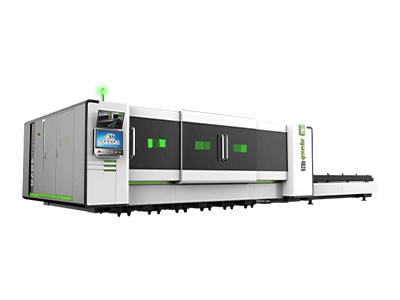

MACH 4020

Since the material does not need to be fixed in place, it will not deform unsightly due to laser cutting. Non-contact, precise and simple-these are the characteristics of laser machines in the automotive industry

HyRobot C20

3D laser cutting adopts non-contact processing. The laser cutting machine has almost no consumables and no pollutants. The 3D laser cutting machine can also solve the problems of partial cutting holes and edge cutting, and can solve the 3D metal forming parts

HyRobot W20

3D laser welding has high flexibility and can be used in any process of any workpiece. When the workpiece product changes, only the offline program of laser welding needs to be changed. It is also very convenient to replace the fixture, which can reduce the investment in the mold and shorten the test cycle of the sample